How often have you driven in icy conditions? Have you ever slammed on your brakes to avoid a collision? The slip and slide of wintry roads is not an experience for the faint of heart, and neither is a situation that requires emergency braking. Drivers are left with a white-knuckled grip on the steering wheel as they recover, hoping to reach their destination safely.

Your brakes are your vehicle’s only stopping power, meaning that any situation that causes a dramatic loss of traction puts you at increased risk. Without traction, your tires are prone to skidding, sending you in any direction and significantly reducing your control behind the wheel. Fortunately, systems like the antilock brakes in your vehicle work behind the scenes to help you maintain that life-essential control. How do antilock brakes work? What’s the history behind this revolutionary feature? Moreover, what can go wrong that leads to a visit to your local dealership for brake service?

Setting the Stage: The Need for Antilock Brakes

Antilock brakes are revolutionary in heightening our safety in the driver’s seat. However, the idea of antilock brakes isn’t a modern invention. The earliest concept of antilock brakes arose in the early 20th century alongside the rise of the automobile, with the railway and aircraft industries testing and eventually adopting the system in the 1950s. Yet, automakers didn’t fully jump on the bandwagon until decades later when organizations like the National Highway Traffic Administration and the Insurance Institute for Highway Safety reported the critical role antilock brakes could play in improving driver safety and mitigating dangerous braking situations.

Nearly every vehicle built since 2012 has antilock brakes, but understanding the system’s ingenuity requires looking at the progression of braking systems. Before antilock brakes, vehicles relied on a conventional brake system that was straightforward but problematic. Sudden or emergency stops using conventional braking caused the wheels to lock up, dramatically reducing the driver’s control as the vehicle began to slide. The only solution was to pump the brakes when the car started skidding. This would allow the locked wheel to begin rolling again, regaining traction and control, at which point the brake could be reapplied to continue reducing speed. However, even a skilled driver doing everything right could experience a significant loss of control, increasing the likelihood of a collision or incident.

Understanding the ABS System: How and Why It Works

Antilock brakes don’t eliminate the need to pump the brakes when your vehicle starts to skid. Instead, they automatically handle the pumping process. They release and reapply the brakes several times per second, much faster than a human driver can pump the brake pedal. Even better, they pump the brakes at each wheel individually, meaning that wheels that have not lost traction continue to get the full amount of braking power, allowing you to stop faster and maintain control. So how does it work?

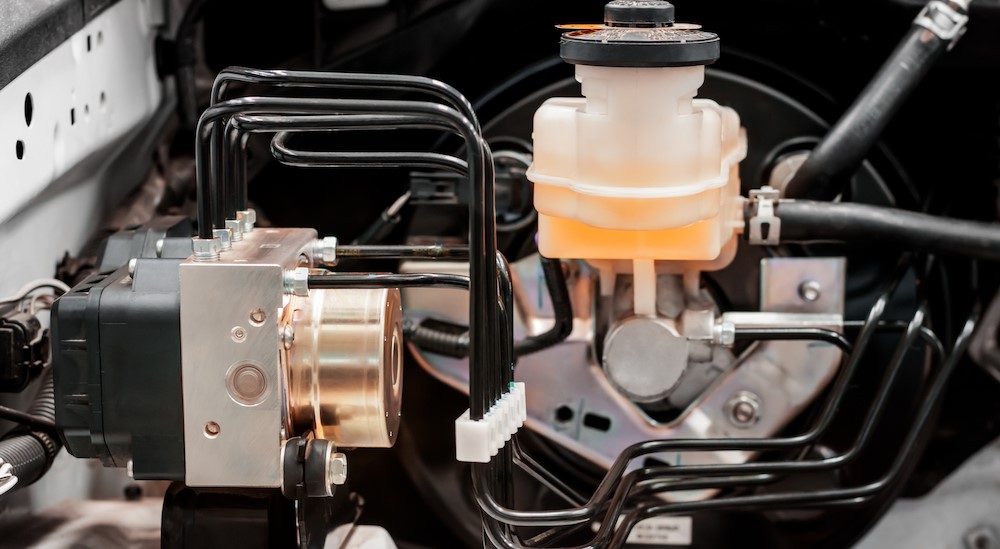

The antilock brake system in your vehicle relies on four basic components: speed sensors, a pump, valves, and a control module. To automate the process of pumping the brakes, the system has to know what’s going on and when to engage. The speed sensors tell the controller what’s going on at each wheel, alerting the control module when a wheel is in danger of locking up. The control module is the computer or mastermind behind the system, utilizing data from the speed sensors to control the valves and pump.

The alert kickstarts the next part of the system, activating the valves. The valves are located in the brake lines and have various positions. For example, some antilock brake systems rely on a three-position valve that either opens to channel pressure from the master cylinder to the brake, blocks the line, or releases some of the brake pressure. This release is critical to the antilock brake system because any released pressure must be rebuilt, which is where the pump plays an essential role. Once the valve releases the brake pressure, the pump increases that pressure to reapply the brake once the speed sensor tells the control module that the wheel is rolling again.

The System in Action

You’re traveling down the highway at 60 MPH when suddenly, a deer runs in front of you, and you have to slam on the brakes. Your vehicle takes around five seconds to fully stop, but the wheels can stop turning in less than a second. This time difference is problematic, setting the stage for wheel lockup, a skid, and a loss of control.

The control module in the antilock brake system notices this rapid deceleration via the speed sensors. It not only notices the vehicle’s rapidly decreasing speed but also whether the speed of one or more individual wheels suddenly drops to zero while the other wheels are still turning, indicating a lockup. The control module tells the valves when and how to respond, reducing the brake pressure until the sensors recognize that the locked wheel is turning again and then increasing the pressure to reapply the brake. This happens instantaneously as you press the brake pedal, slowing your tires to the same rate as your vehicle while preventing them from locking up or skidding. As a result, you have optimal braking power and more control over your car. A skidding wheel can’t steer, so antilock brakes retain steering control by preventing a skid while improving stopping distance. If you can’t stop quickly enough to miss the deer, you can still swerve around it since your wheels aren’t locked.

Antilock Brakes: Signs of Trouble

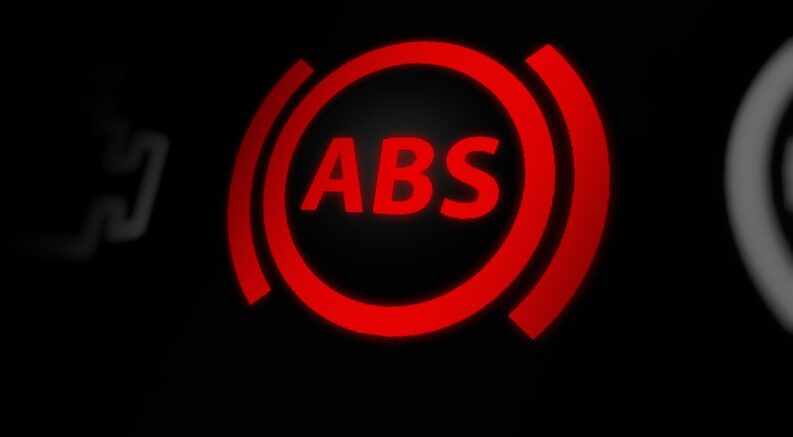

Your vehicle’s antilock brakes work quietly behind the scenes to heighten your control and optimize your braking power. When you see a dashboard light that signifies trouble with the system, it’s essential to bring your vehicle in for brake service. A technician can diagnose the system, determining the cause of that pesky and worrisome dashboard light.

Malfunctioning Control Module

The control module is the antilock brake system’s computer. In rare instances, the control module malfunctions because of interference with other systems. For example, the antilock brake system works with your vehicle’s traction control system, often sharing a module. Because of this, the systems can interfere with one another, meaning the ABS light on your dashboard might signal an issue with the traction control system. In either instance, a technician can run diagnostics to determine the cause.

Low Brake Fluid

Your vehicle’s brake system is hydraulic, meaning it relies on fluid to create the necessary pressure to engage components like the brake pads to stop your car. Think of the valves in the brake lines and how they operate in various positions, letting pressure from the master cylinder through, blocking it off, or controlling its release. When brake fluid is low from a leak or another issue, your antilock brakes won’t operate optimally. Some antilock brake systems even have a separate brake fluid reservoir from the main one. Both must be filled up with fresh fluid for optimal performance.

Broken or Malfunctioning Sensors

One of the most common issues with antilock brakes is broken or malfunctioning wheel sensors. The sensors are positioned at the wheels, exposing them to a harsh environment that leaves them prone to dirt and other debris. Sensors can easily get dirty and trigger a warning light on your dashboard. When this occurs, the sensors must be cleaned or replaced.

Wiring Issues

Like the speed sensors at each wheel, the wiring in the antilock brake system can experience wear and tear because of the environment. For example, your vehicle’s natural vibrations can cause the wiring to disconnect or break, leading to a dashboard ABS indicator. In other instances, the environment may cause the wiring to become exposed, a dangerous situation that requires immediate attention at your local service center.

Safety in the Driver’s Seat

You probably don’t give much thought to your vehicle’s stopping power, at least not until you’re forced to slam on the brakes. Even then, your white-knuckled grip on the steering wheel skyrockets your adrenaline as you recover and hopefully regain control over your vehicle. Behind the scenes, you have antilock brakes to thank for helping you maintain control.

When you see an ABS indicator on your driver dashboard, don’t hesitate to bring your vehicle in for brake service. The antilock brake system is a life-saving tool recognized industry-wide by the National Highway Traffic Safety Administration and the Insurance Institute for Highway Safety. The statistics tell the same story, with antilock brakes reducing collisions by up to 8% and fatal accidents by 12% on wet, icy, or snowy roads. Fatal collisions involving animals, cyclists, and pedestrians are also reduced by 14%.

Consider the numbers and your safety in the driver’s seat. Also, remember that tools like the antilock brake system are only part of your safeguard. You’re also responsible for your driving habits and can dramatically reduce the likelihood of relying on the antilock brake system by slowing down and staying focused when you’re behind the wheel.