As increased government regulations and a general shift toward more environmentally responsible technology has many auto manufacturers looking to downsize overall engine size, an age-old technology is allowing them to deliver the same power and performance drivers have become accustomed to. Once reserved for high-performance vehicles, heavy construction equipment, and niche luxury brands, turbochargers – and to a lesser extent, superchargers – have come into the mainstream of late as automakers turn to the technology to increase efficiency and meet increasingly strict emissions standards.

While these two technologies differ in some important ways, both rely on the same basic principle: the more oxygen-rich air you can force into an engine, the more performance you can get. The recent industry-wide embrace of this principle (known as “forced induction”) marks a shift from traditional naturally aspirated engines and allows automakers to pump the same amount of air into smaller engines, delivering comparable power in a more environmentally-friendly package. But how do they work? Which one is better, and why are they so vital in helping automakers hit mandated Corporate Average Fuel Economy (CAFE) standards? Let’s take a closer look and find out.

Blowing In The Wind

First, a little Chemistry 101. In order for any combustion reaction to take place, you need three distinct elements: fuel, heat, and oxygen. The more oxygen you can pump into the system, the more efficient – and therefore powerful – the reaction. Turbochargers and superchargers are both used to increase the amount of oxygen available in the combustion chamber, though they go about it in slightly different ways. Turbochargers capture hot exhaust gas before it can be expelled from the vehicle, using this otherwise wasted energy to power a small compressor (turbine) that feeds more oxygen-rich air into the engine.

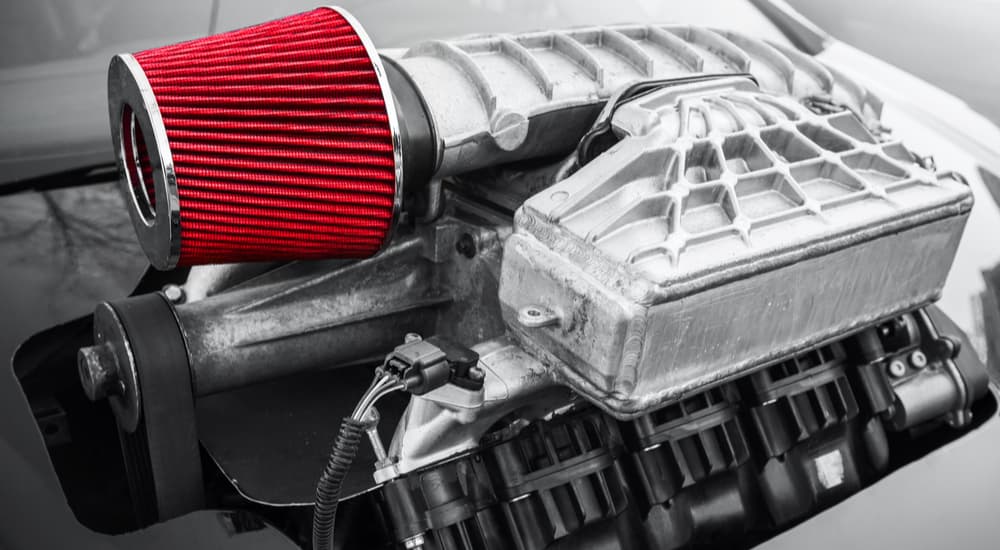

Car Superchargers, on the other hand, accomplish the same trick without relying on exhaust fumes for power. Instead, superchargers run off a belt connected to the crankshaft or via their own electric motor. This method might seem counterintuitive to some since the supercharger needs to rob the engine’s horsepower in order to operate, but it’s still a net gain in the end. A supercharger can eat up as much as 20 percent of an engine’s power but typically increases performance by between 30 and 50 percent – more than making up for the power siphoning.

We should also take a minute to mention cold-air intakes, which also work to increase available oxygen, though in a slightly lazier way. Where turbochargers use escaping gases for power and superchargers borrow direct mechanical energy from the crankshaft or electric motor, the cold air intake is a far more passive technology. These typically aftermarket parts are located further from the engine than normal air intakes, allowing them to collect cleaner, cooler, and more oxygen-rich air. Cold air intakes operate without any compressors, fans, or outside power, making them much cheaper – but also much less efficient – than turbochargers and superchargers.

Turbochargers date as far back as 1915, when they were developed to help aircraft generate more power in the thinner, less oxygen-rich air found at high altitudes. Initially dubbed the turbosupercharger, the name was simplified over the years and is now commonly referred to as a turbocharger or often simply a turbo. Supercharger tech is even older and can trace its roots back to the Roots blower of 1859, which was used to improve the efficiency of industrial blast furnaces. Superchargers migrated to combustion engines in 1878, soon after the gasoline engine was developed.

Mercedes-Benz was the first manufacturer to roll out a supercharged production vehicle when it introduced the Kompressor model in 1921, but a turbocharged car didn’t appear until the 1962 Oldsmobile Turbo Jetfire. We know that anything with “turbo” or “super” in the name inevitably sounds like a cheap marketing ploy, but in this case, it’s something of a chicken-and-egg situation. While we can’t account for “super,” the word “turbo” and all its extreme connotations actually come directly from turbocharging technology itself.

Head-To-Head

So we know how they work, but which one is better? Well, it depends on a driver’s intended use. We’ll get a little deeper into the weeds here, but in short: If you want to downsize your carbon footprint but don’t want to sacrifice power, go for the turbo. If you’re looking to tear up the quarter-mile and glue the back of your skull to the headrest, then the turbocharger is also for you. However, if you are seeking the smooth linear acceleration of a naturally aspirated engine with a bit more power, look for a supercharger.

Turbochargers and superchargers both help in getting that little extra oomph out of your ride, and while this is still largely true of superchargers, turbochargers are finding renewed popularity as a way of delivering increased power from smaller engines in order to meet environmental standards. The numbers don’t lie: in 2018, there were 220 models on the market with turbo engine options, compared to 30 with a supercharged setup. There are a few reasons turbochargers are better suited to this role, so let’s dive a little deeper and explore the big differences between these two forced inductions technologies.

For the average driver, the difference between a supercharger and a turbocharger is going to come down to patience. Since a turbocharger needs a steady diet of hot, fast exhaust fumes to do its thing, there is a bit of a lag compared to independently-powered superchargers. This spooling up or “tubo lag” as it’s called, isn’t much of a hindrance for most drivers, though in high-performance motorsports, that little lag could make all the difference. A supercharger’s advantage lies in its ability to deliver instant power, though the definition of “instant” varies a bit. Superchargers are broken down into two categories: Roots-type and centrifugal. The former is the oldest and most common on the market today, and while it’s less efficient than some newer designs, it has the advantage of providing a boost even at lower RPMs. Centrifugal superchargers are more efficient and compact but don’t work well at lower RPMs.

While turbos are currently the forced air induction method of choice for mass-market cars, superchargers could well be poised for their own moment in the spotlight. With the steady advance of EV technology opening the door to new automotive experimentation, some automakers have started exploring ways to use the vehicle’s excess juice to power a new generation of superchargers. All electric and many hybrid vehicles feature regenerative braking, a technology that uses the electric motors as generators to capture the energy from deceleration and braking. While this energy is usually fed back into the vehicle’s battery pack as a way to increase range, it can easily be routed to a supercharger that doesn’t need to borrow a horsepower off the engine to operate.

It’s little surprise that supercharger forerunner Mercedes-Benz has taken the lead on this updated concept, with the CLS53 and E53 both offering engines which repurpose brake-powered electricity to power their superchargers. The vehicle’s 429-hp 3.0-liter V6 already has turbos, so what exactly does a supercharger add to the equation? It eliminates that pesky turbo lag, filling in the gap as the turbocharger spools up and delivering a seamless burst of power.

Forced Induction is Here to Stay

The renewed interest in turbo technology has already started to change the industry as a whole. The increased performance enabled by forced induction is allowing automakers to dramatically downsize their engines, with turbocharged four-cylinder engines replacing V6s and turbo V6s replacing V8s. These innovative combinations not only allow drivers to experience the same power they expect out of their vehicle but can actually provide more torque than larger engines that don’t feature forced induction. Turbos are already becoming more ubiquitous as brands continue to innovate their way to cleaner, more efficient vehicles, and superchargers aren’t far behind with the potential offered by the steady stream of electricity supplied by EV’s regenerative braking. From airplane engines built over 100 years ago to a new generation of efficient, greener vehicles rolling off assembly lines today, forced induction technology is a vital tool for getting the most out of your engine.