From performance upgrades and safety systems to convenience and comfort features, there have been countless advancements in automotive technology since the first gas-powered car was produced in 1886. We tend to take such features for granted, but it’s hard to imagine getting behind the wheel of a vehicle that lacks an electric ignition starter, seat belts, windshield wipers, coil-spring suspension, or any of the other improvements that have graced the industry over the last 100-plus years.

While there’s certainly no discounting the importance of vital features like airbags or anti-lock brakes, one unheralded feature that dramatically impacts our everyday safety and comfort is power steering. We all remember what it’s like to ride in a car before GPS and Bluetooth connectivity, but few drivers on the road today remember what it’s like to coax a car around a corner in a pre-power steering model. Read on as we dive into the history of power steering, learn more about how it works, and review some common power steering malfunctions.

What Is Power Steering?

As the name implies, power steering is a system that uses some form of mechanical assistance to reduce the amount of effort it takes to turn the steering wheel. While it’s often overlooked today, it’s a major improvement over earlier technology. Before the advent of power steering, a vehicle’s steering systems were geared in such a way that a driver was required to turn the wheel to the left or right countless times to navigate each turn. Power steering multiplies the force of every turn, allowing drivers to glide through corners without spinning the wheel like some grizzled boat captain navigating through rough seas.

Power steering made its first appearance on a five-ton Columbia truck in 1903, where electric motors were used to help turn the weighty vehicle’s front wheels. The technology would be patented by one Robert E. Twyford of Pittsburgh, but wouldn’t make its way into a production vehicle for another 50 years. In the meantime, the technology was refined by automotive engineer Francis W. David during his tenure at Pierce-Arrow, General Motors, and finally, parts manufacturer Bendix. One of the technology’s first applications would be seen on heavy armored cars and tank recovery vehicles for the British and American armies during WWII, but the public would come to know about power steering thanks to the 1951 Chrysler Imperial.

Chrysler’s full-size luxury car was the perfect palace to showcase a wide range of new and emerging automotive tech, including a power steering system based on Davis’ patents, which was marketed under the name Hydraglide. General Motors would follow suit with a power steering-enabled Cadillac in 1952, cementing power steering’s status as a must-have feature. While the power steering concept had been sitting on the shelf for decades, the increasing trend towards heavier vehicles with wider tires and front-wheel drive quickly made it a necessity.

Hydraulic Vs. Electric

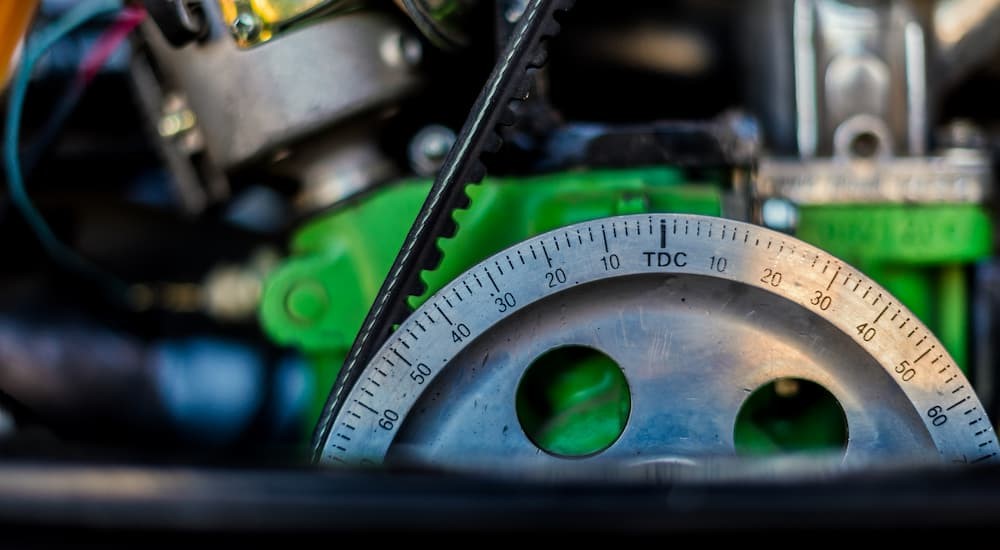

From the 1950s to the early 2000s, most power steering systems relied on hydraulic assist to get the job done. In such a system, hydraulic fluid is pressurized by an engine-driven pump. When a driver goes to make a turn, the steering wheel acts as a valve to control the flow of hydraulic fluid to a double-acting hydraulic cylinder that applies force to the steering gear and, ultimately, the wheels themselves. The more you turn the wheel, the more hydraulic force is exerted on the cylinder, drastically multiplying the force a driver can exert when it comes time to make a turn.

While hydraulic power steering (HPS) has served the industry well for 70-plus years, it does have a few drawbacks. First, the hydraulic fluid pump- connected to the engine by the serpentine belt- needs to be constantly running even when moving in a straight line, creating some inherent inefficiencies. The hydraulic fluid also needs periodic replacement and can leak if the power steering lines become old, worn out, or damaged.

These drawbacks have led the industry to develop an improved version of power steering known as electric power steering (EPS). Instead of a system of pumps, reservoirs, and hoses, EPS uses an electric motor to translate a driver’s steering wheel inputs into action. EPS is a little more complex than HPS as it can tailor the amount of steering assistance based on speed, steering wheel torque, and other factors. At low speeds, EPS uses a light touch, giving drivers the precise control essential for parking and other such applications. EPS takes a more active role when moving at faster highway speeds, amplifying the steering power to improve control and stability behind the wheel.

The electric motor in an EPS system is usually located on the steering rack, which is common in sports and luxury vehicles, or on the steering column itself. The EPS approach has a few advantages over HPS, especially regarding efficiency. The electric motor isn’t directly powered by the engine, which aids in fuel economy and emissions. It’s also less messy than HPS, with no hydraulic fluid leaks or burst hoses to worry about.

Finally, it’s reliable. If the engine fails in an HPS-enabled vehicle, power steering goes right along with it, but that’s not the case in a vehicle equipped with EPS. EPS is also customizable by vehicle type, road speed, and even driver preference, and it eliminates environmental hazards of leakage and disposal of hydraulic power steering fluid. Without EPS, many of today’s advanced driving assistance systems (ADAS), such as lane-keep assist and automated parking, wouldn’t be possible.

We’ll also take a moment to mention electrohydraulic steering. This power steering approach is rarely found outside heavy-duty pickups and represents a synthesis of the two technologies mentioned above. Electrohydraulic steering mostly works like an HPS system, but the hydraulic pressure is created by an electric motor instead of feeding off belt-driven engine power. This system eliminates the inefficiencies of an HPS system but lacks much of the ADAS-enabling automation found in pure EPS systems.

Common Causes of Power Steering Failure

A power steering issue is one of the easier automotive issues to diagnose. If you go to turn your wheel and are met with an unusual amount of resistance, strange noise, and a general lack of cooperation, you’re probably looking at an issue related to the power steering system. So, what causes these symptoms? Let’s take a closer look and see how easy it can be to diagnose a power steering-related issue from the comfort of your own driveway.

Power Steering Fluid Leak

In an HPS system, a loss of power steering fluid is one of the most common causes of lackluster performance. An HPS system is naturally going to lose some fluid in the course of operation, but a sudden loss of fluid — accompanied by a large wet spot in your driveway — could indicate a burst hose or loose connection in your power steering pump, rack-and-pinion, or steering gear. In addition to making the wheel more difficult to turn, low power steering fluid can also cause a whining or squeaking noise as the power steering pump struggles to do its job.

Power Steering Pump Failure

The power steering pump is responsible for pressurizing the HPS system and can create some problems when it’s not working properly. Generally speaking, a power steering pump should last for the life of a vehicle, but things happen. Using the wrong type of power steering fluid is one quick way to prematurely age your power steering pump, which is why it’s important to not just reach for the first bottle you find at the auto parts store. Most power steering fluids are interchangeable, but certain brands like Honda use their own proprietary blend specially formulated for the pumps found in their vehicles. Running chronically low on power steering fluid is another way to stress out your power steering pump, as a lack of power steering fluid can cause premature wear on the pump itself.

Air in the System

When the hoses or lines that make up your HPS system are damaged or spring a leak, air can find its way into the system, which can lead to jerky, unresponsive steering that can make a vehicle difficult to control. If you’ve noticed inconsistent performance when you go to turn the wheel, it could be time to inspect your power steering system for a leak. These leaks are commonly found in a fitting attached to the low-pressure return line or a rip or tear in the return line hose itself.

Damaged Belt

In an HPS system, the power steering pump is powered by the engine itself, or more precisely, by the serpentine belt. This belt attaches to the engine and feeds power to a number of systems throughout the vehicle, including the power steering, alternator, and air conditioning. Serpentine belts are designed to last 60,000 to 100,000 miles but can become worn out or broken over time. When this happens, you’ll generally know in a hurry, as it can manifest in everything from a lack of A/C and power steering to a dead battery. Luckily, a serpentine belt is a quick and affordable fix, ranging between $70 and $200.

Bad Steering Rack Mount

Most vehicles rely on a rack-and-pinion steering system to convert rotational motion (turning the steering wheel) into the type of linear motion needed to adjust the angle of the tires. If your car starts to wander to the left or right or create a distinctive grinding noise when turning at low speeds, you could be looking at a faulty steering rack. In most cases, the problem can be fixed by replacing the steering rack bushing, but in some cases, an entirely new mount might be in order.

Electrical Issues

We’ve covered some of the basic causes of failure in an HPS system, but what about EPS? In many ways, EPS systems are much simpler than their HPS forerunners, but they’re still prone to failure. EPS systems use an electric motor, an electronic control unit, and a network of sensors to do their things, and a failure in any of these components can easily lead to some serious problems when it comes to steering. Luckily, many of today’s EPS systems come with their own warning light that will alert you to any issues well before you make a turn. If your vehicle is equipped with EPS and you’ve noticed poor power steering performance, don’t waste your time looking for belts or leaks: take it directly to a trusted mechanic for a once-over.

Know What to Look For to Identify Potential Problems

Power steering might lack the convenience of an in-vehicle Wi-Fi hotspot or the luxury of heated, massaging seats, but there are a few features that are quite as important when it comes to automotive safety and control. If you notice any of the tell-tale signs of a faulty power steering system, including difficult turns, squeaking or grinding noises, leaks near the front wheels, or a vehicle that wants to pull to the left or right, it might be time to call in the experts.

Some power steering fixes — like topping off the power steering fluid or replacing the serpentine belt — might be well within the reach of the average home mechanic, but for anything more complex, we’d recommend a visit to your trusted local mechanic or dealership. Given its importance when it comes to overall vehicle safety, power steering-related issues are best left to the experts.